Production Lines

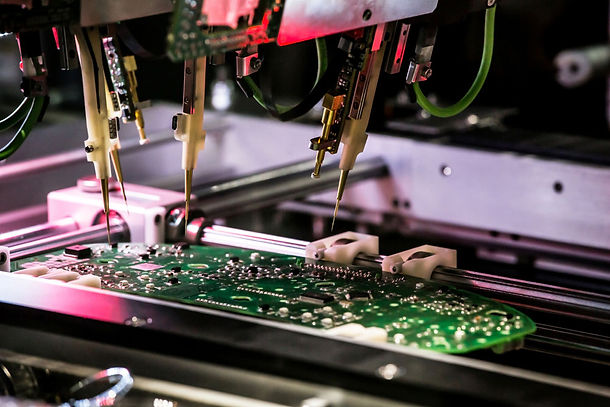

At our facilities, we specialize in complex electronic components tailored to the stringent automotive and IoT industries' specifications. While we exclusively manufacture our own products, our capabilities extend far beyond mere production.

Our expertise lies in the complex assembly of electronic boards engineered to thrive in demanding environments. From navigating limited size constraints to conquering extreme operating conditions such as temperature fluctuations and intense vibrations, and multi-layering requirements, we excel in pushing the boundaries of electronic design.

Our production lines are optimized for efficiency and accuracy, and we boast the capacity to handle projects of remarkable complexity. Our adeptness extends to boards spanning up to 32 layers, a testament to the sophistication of our processes.

Within our facilities, cutting-edge technologies and state-of-the-art machinery converge to bring visions to life. Rigorous testing techniques ensure the reliability and performance of every component that leaves our production lines.

Supply Chain

Semiconductors and Connectors

Addressing global challenges requires a collective effort, involving individuals, governments and organizations. Collaboration is essential to tackle problems effectively and capitalize on opportunities. At KEENG, we are dedicated to pursuing the next innovation by collaborating closely with a network of esteemed partners.

Quality Control

Functionality Testing

In both the Automotive and Communication & IoT industries, functionality testing plays a crucial role in ensuring the reliability and performance of electronic devices. This testing involves conducting various critical logic and signal state assessments under specific operational conditions, including the device's default operating state. The analysis includes assessing peripheral circuit adjustment, control, signal amplification or conversion matching.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) technology revolutionizes visual examination processes during electronic manufacturing. It significantly enhances product quality by swiftly identifying flaws throughout the production phase. AOI employs advanced optics, camerasand image processing capabilities for its inspection tasks, crucial for the safety and security needed in both Automotive and IoT & Communication applications.

AOI meticulously scans for defects, surface imperfections and overall quality discrepancies and functions as an industrial inspection machine, utilizing digital cameras or scanners alongside AI algorithms, for heightened speed, accuracy and uniformity.

In-Circuit Testing (ICT)

In-Circuit Testing (ICT) is a vital technique for examining individual components and connections on a populated printed circuit board (PCB) to ensure proper functioning. ICT works by evaluating electrical characteristics at specific points on the PCB, confirming that each component operates as intended within the broader circuit. This thorough assessment of the PCB's integrity is essential for upholding product quality standards for the Automotive, Communication IoT and Industrial IoT industries.

ICT testers are available in various configurations, ranging from benchtop testers suitable for low-volume production to automated systems for high-throughput mass production.